Products

Among the innovative wastewater treatment solutions offered by Siriusbwa Fibertechnology Kft., the CO²Smart technology plays a prominent role, aimed at improving the efficiency of modern wastewater and sludge treatment processes. Siriusbwa Fibertechnology Kft.'s goal is to contribute to the reduction of environmental impact, optimization of operational costs, and enhancement of the performance of wastewater treatment plants.

CO²Smart

The CO²Smart system plays a key role in the rationalization of energy use and cost reduction. With the guiding figures and optimization suggestions provided by the system, wastewater treatment plants can identify and implement changes that significantly reduce their energy consumption. Additionally, CO²Smart contributes to the enhancement of dewatering efficiency, resulting in further cost savings and reduced sludge transportation needs.

Another advantage of the technology is its significant contribution to minimizing carbon dioxide emissions. Thanks to the optimization suggestions provided by the CO²Smart system, wastewater treatment plants can operate not only more economically but also more environmentally conscious, thus actively participating in the fight against global climate change.

CO²Smart App

Mobile Screw Press

In cooperation with CO²Smart technology, the mobile screw press technology enables the optimization of sludge treatment processes, achieving exceptional results in both cleaning efficiency and in terms of chemical and labor costs. This combination promotes the economical and efficient operation of wastewater treatment plants.

Screw Presses

The lamella screw press with a Hungarian-language touch screen is designed to optimize water treatment processes, providing outstanding efficiency in sludge management. Our international collaboration with one of the world's largest manufacturers enables this technology to reach a wider audience, while the green water treatment chemicals produced at the SiriusBWA facility in Sajóbábony contribute to sustainable operation.

The lamella screw press technology supports the economical and efficient operation of wastewater treatment plants while reducing chemical and energy costs.

Our screw presses are available in the following versions:

- BWA 202: up to 104 kgDS/h

- BWA 302: up to 260 kgDS/h

- BWA 303: up to 390 kgDS/h

Available with or without a conveyor screw to meet the specific needs of your plant.

Maintenance Service

Our operating hour-based maintenance contracts ensure long-term, seamless operation, with service scheduled every 500 operating hours or every 60 days.

The lamella screw press technology represents the intersection of innovation and sustainability, helping our partners elevate the efficiency of sludge management processes to a new level.

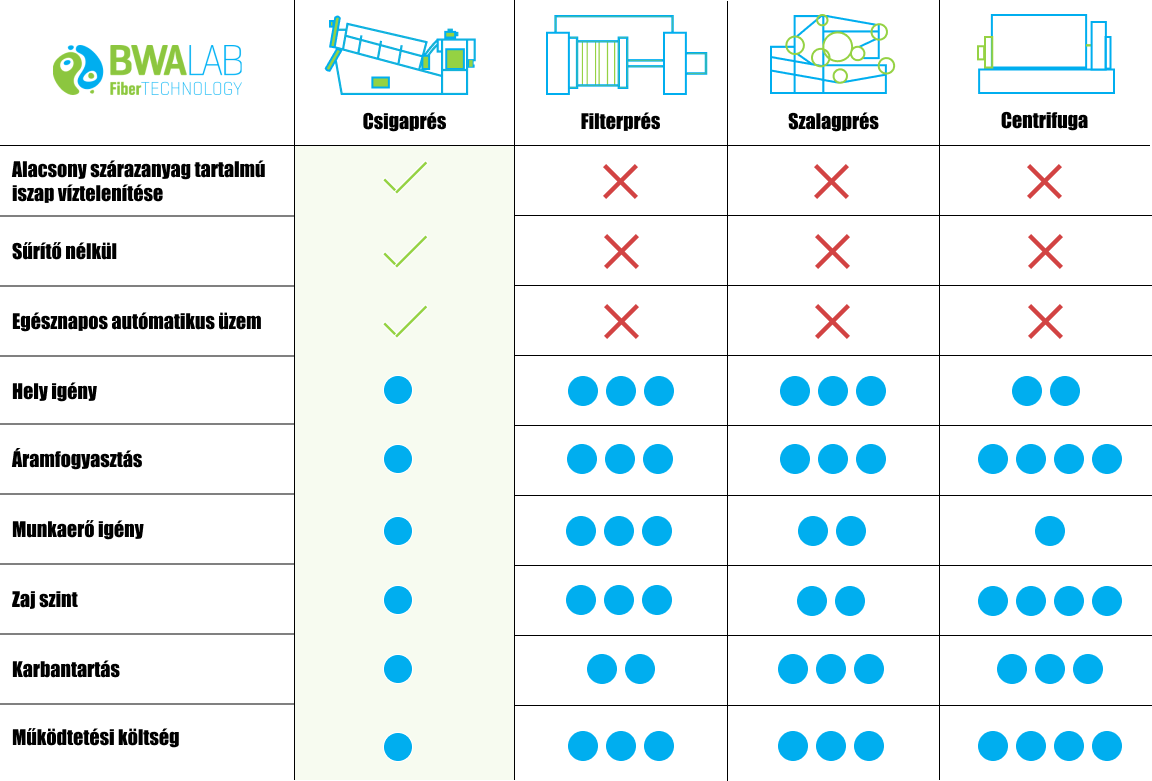

Comparison of Different Press Technologies:

BWA Nanosmart Family

The additives offered by Siriusbwa Fibertechnology Kft., including the Nanosmart GREEN and RED products, play a critical role in achieving the optimal parameters calculated by CO²Smart. These additives have been developed to enable plants that are overloaded or not operating optimally to achieve optimal operational parameters, thereby improving the performance and efficiency of wastewater treatment plants. The use of such additives is indispensable for adhering to the numbers calculated by CO²Smart and improving energy and environmental performance.

BWA Nanosmart GREEN

This product specifically targets nitrogen removal in an anoxic environment, facilitating the improvement of the efficiency of biological wastewater treatment processes.

BWA Nanosmart RED

The RED variant optimizes dewatering processes, especially in the management of high organic load, thereby improving the efficiency of dewatering and contributing to the restoration of plant balance.

Siriusbwa Fibertechnology Kft.'s CO²Smart solutions and the specific chemicals associated with them enable wastewater treatment plants to operate in the most economical and environmentally friendly manner while achieving and maintaining optimal operational parameters.